M

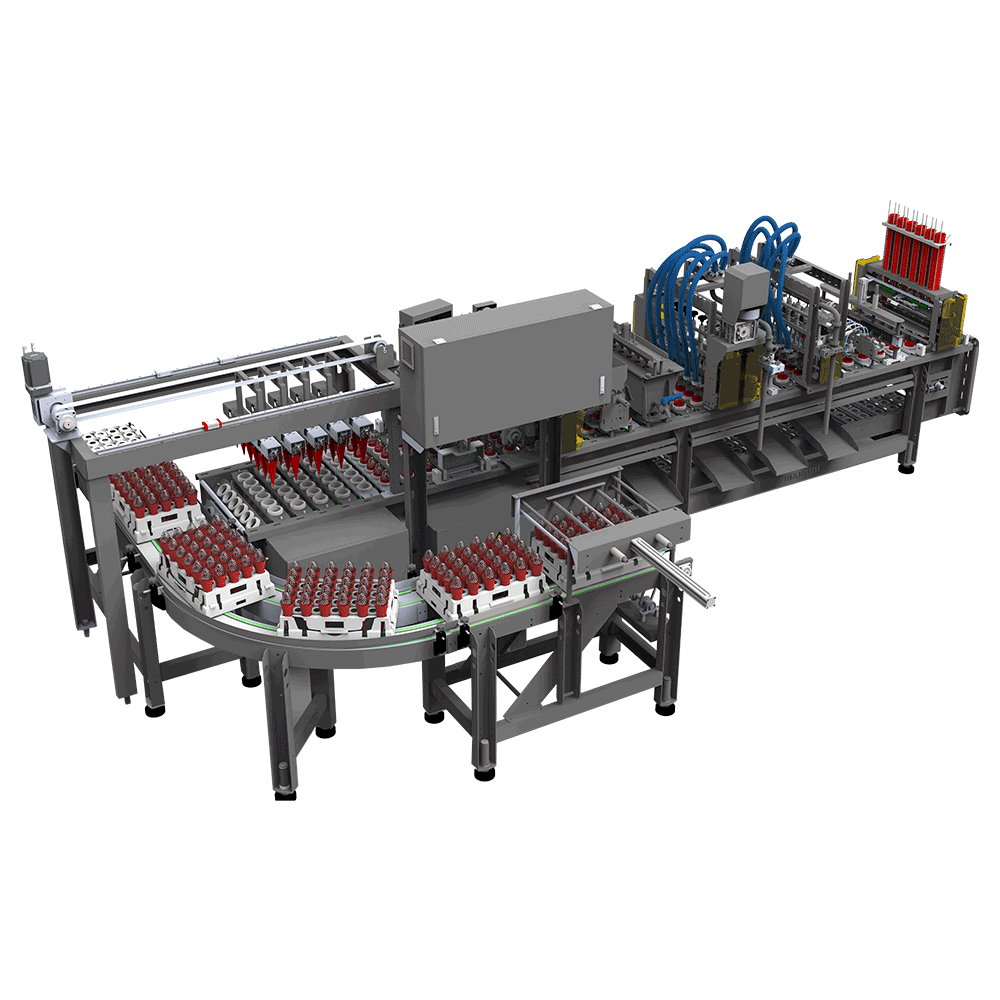

Produce Any Ice Cream Cone or Cup Product

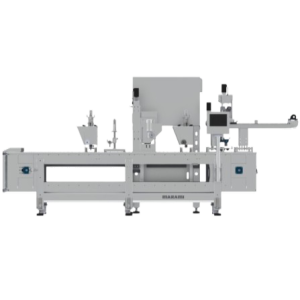

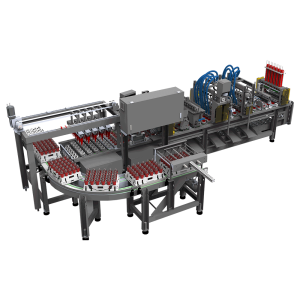

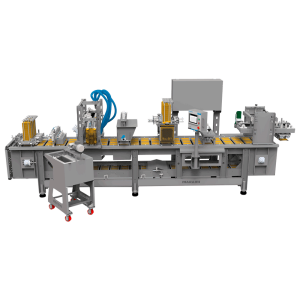

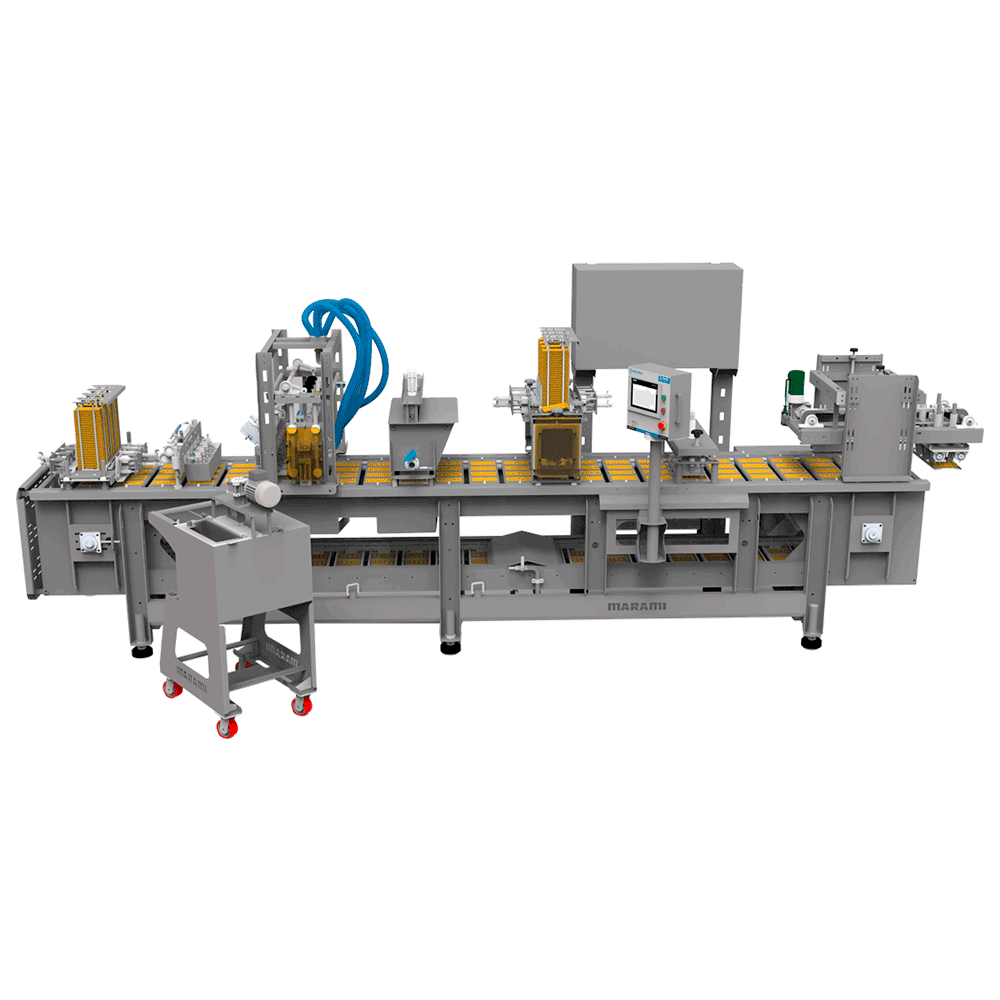

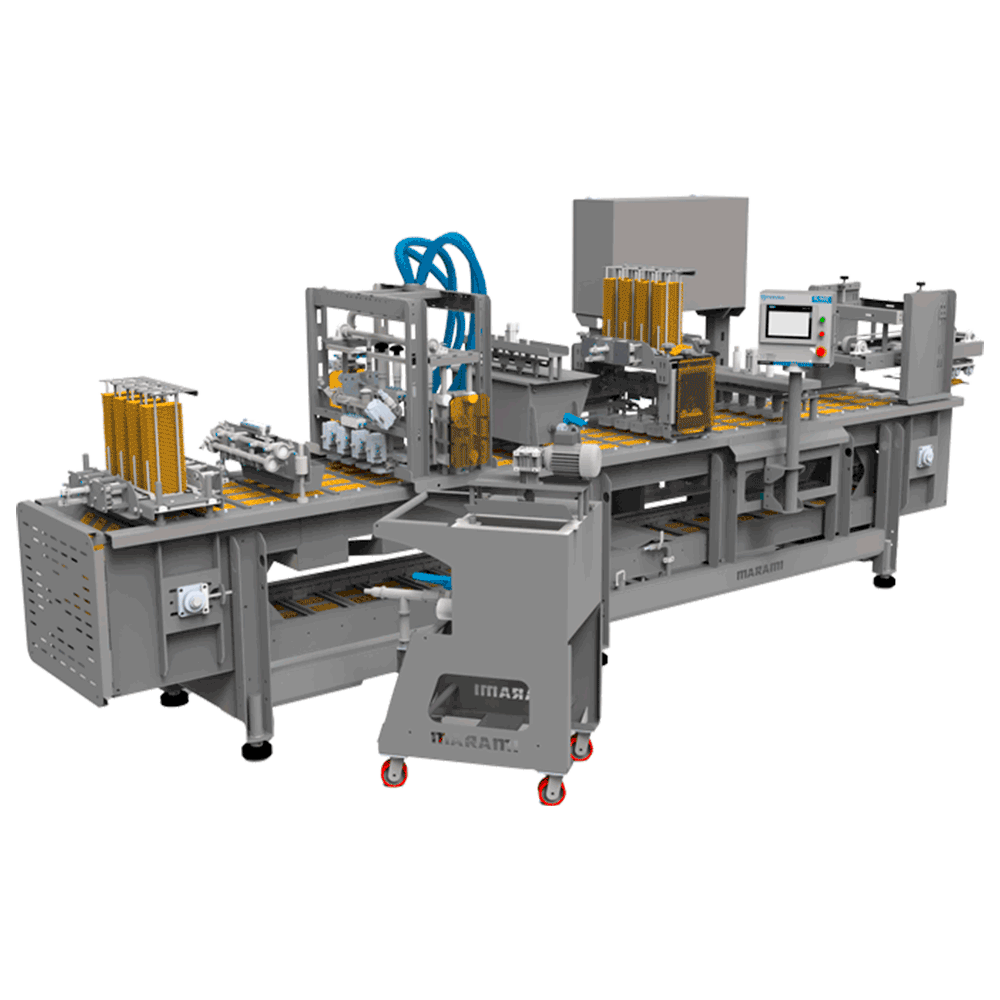

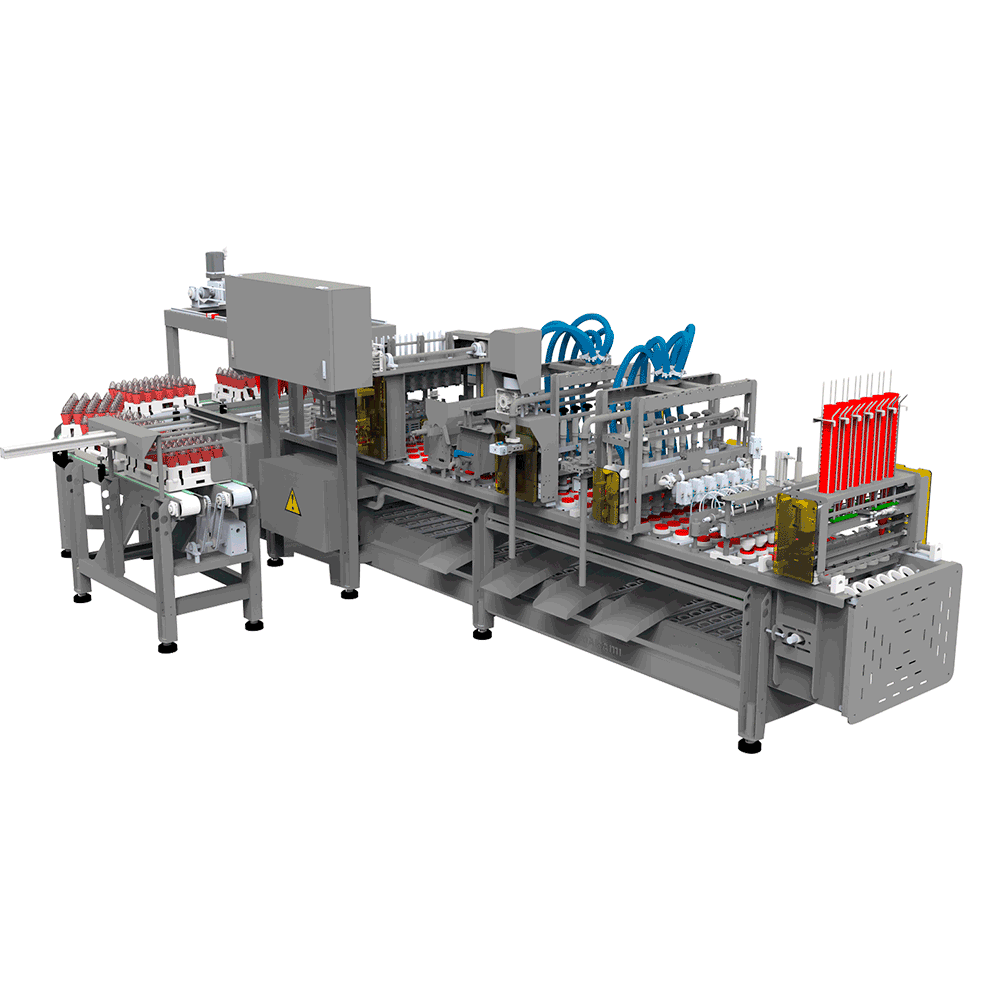

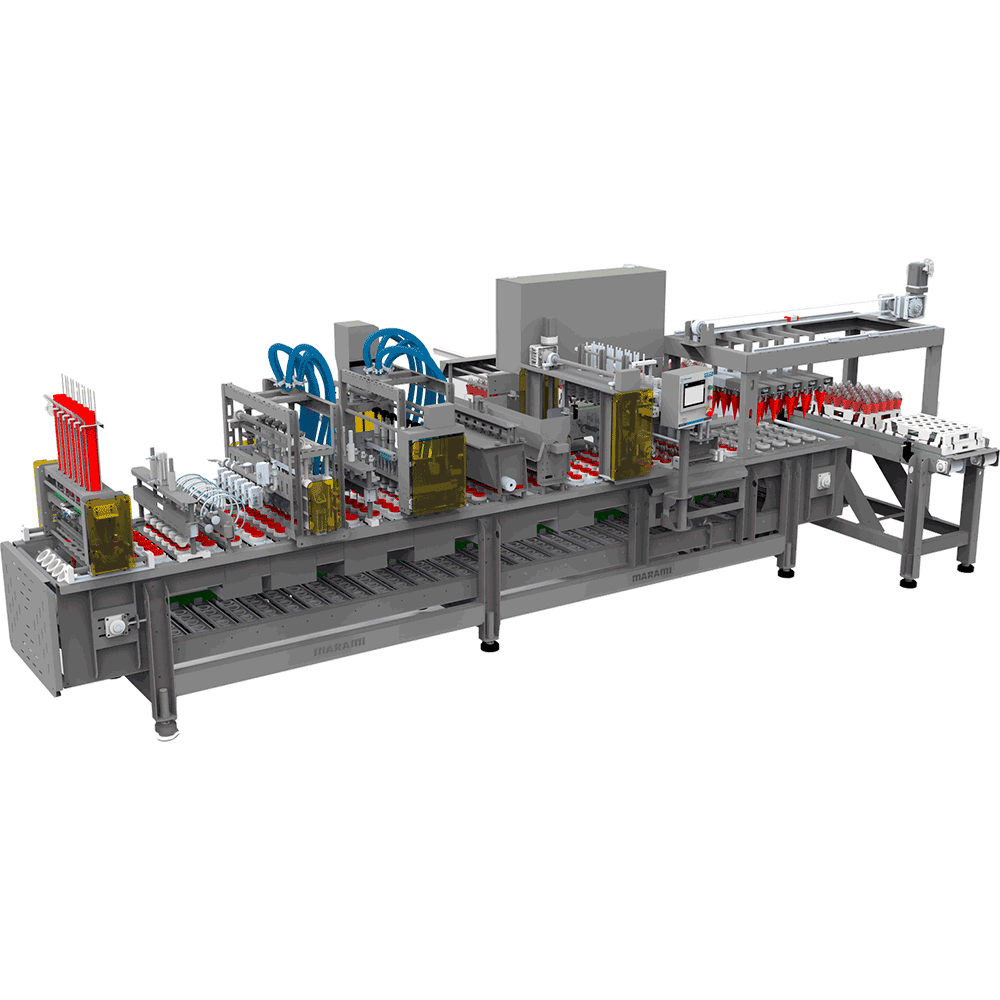

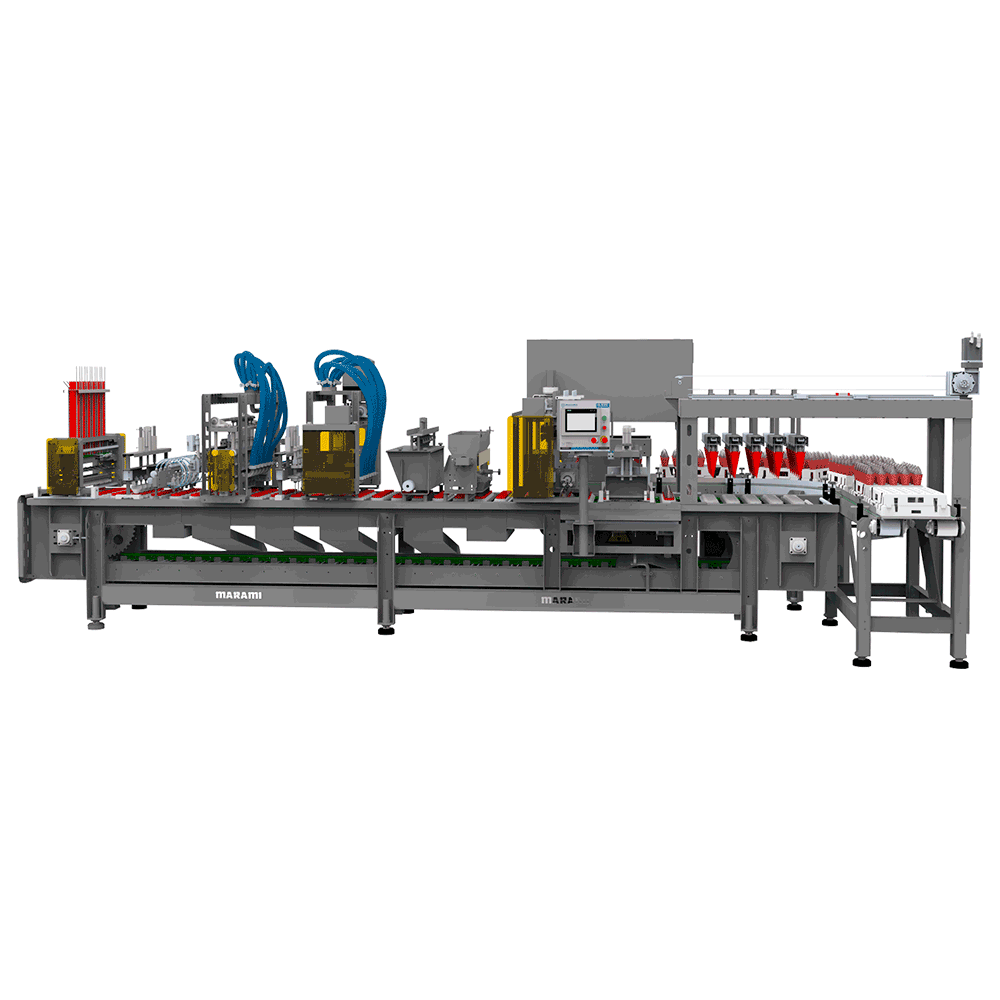

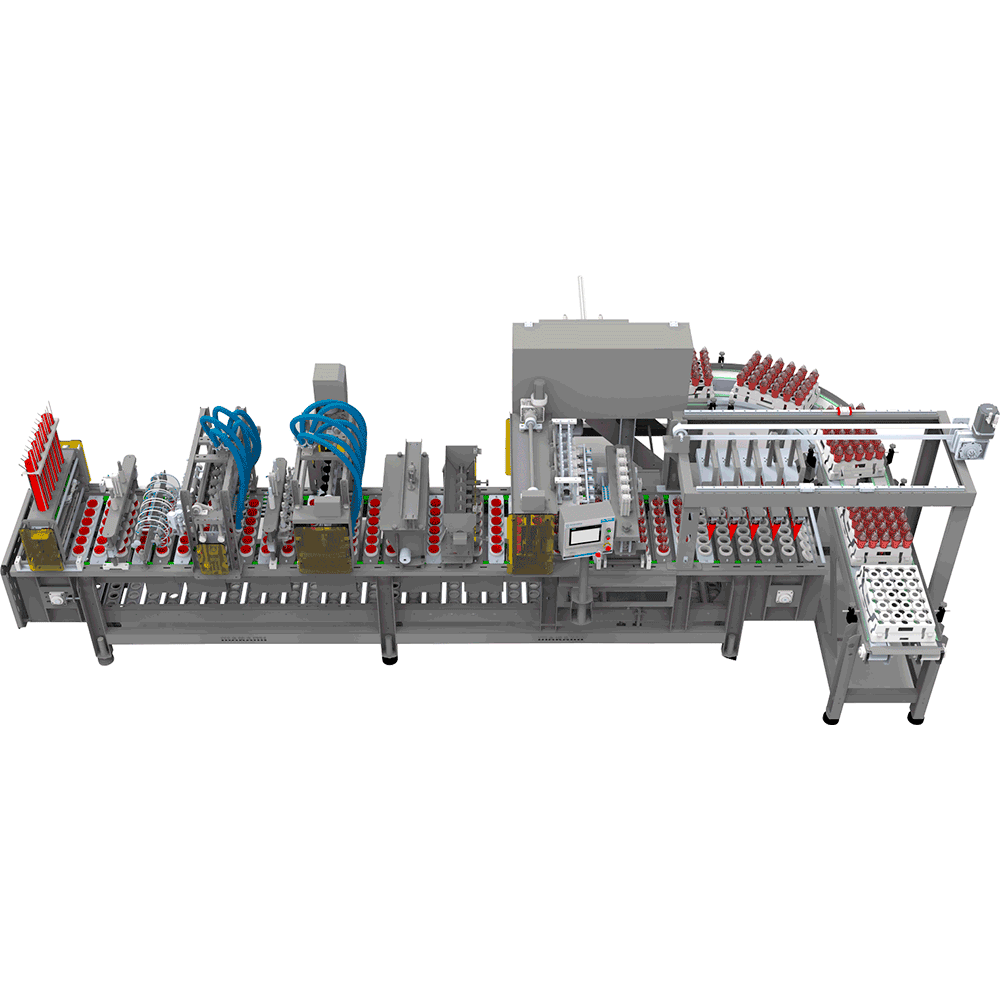

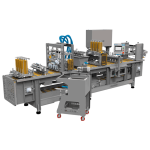

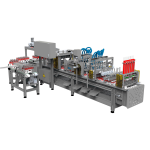

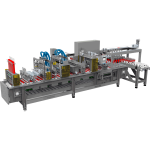

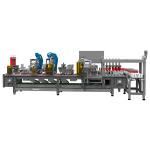

Manufactured by Maramico, this state-of-the-art filling line is designed for producing up to 45,000 ice cream cone and cup products per hour. With a maximum of 10 lanes, it offers exceptional versatility to produce up to four different varieties simultaneously. Whether flat or ball top cones, cups and tubs in multiple shapes and sizes, or even logs and cakes in various formats, this line handles it all. The system supports diverse filling options, including side-by-side filling, tulip designs, flames, chocolate curls, windmill patterns, nuts, sauces, liquid chocolate, chocolate discs, and decorative pencils. The possibilities are limitless

Maximize Capacity, Yield, and Uptime

Run at peak industry capacity with a machine offering unparalleled flexibility. Automated changeovers ensure quick product switches, and its automated cup and lid supply systems are specifically designed to maximize throughput.

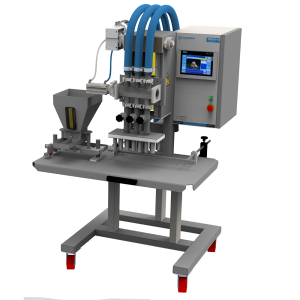

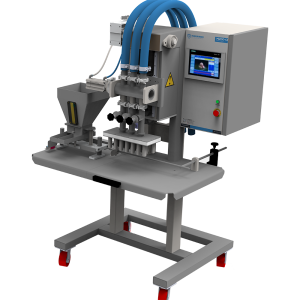

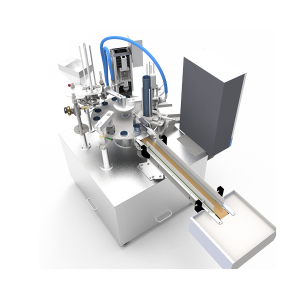

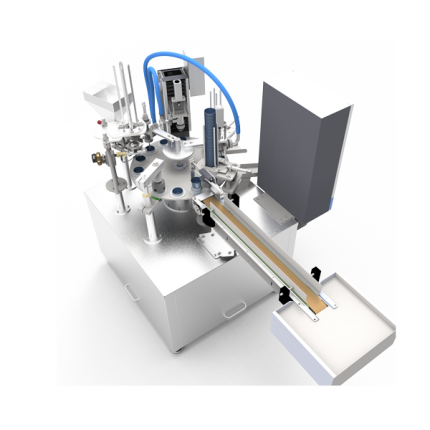

A High-Performance Ice Cream Filler

The Maramico Choice Filler is the perfect solution for cone and cup filling. With the ability to switch seamlessly between different products, it allows you to customize capacity and product range to suit your requirements.

Minimal Waste, Maximum Food Safety

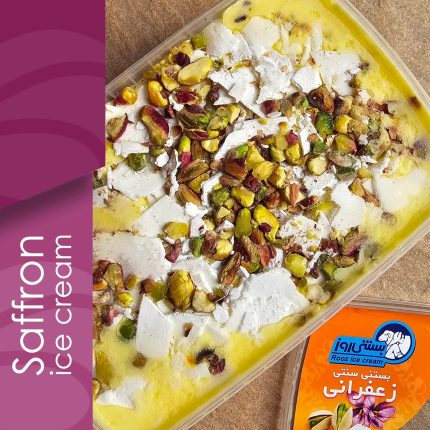

Products of the Maramico linear filling Machine

Products of the Maramico linear filling Machine

Click on each product to view details.

Click on each product to view details.

MARAMICO

Premium Components for Superior Performance

Using the Best Brands in PLC and Pneumatic Systems

Our machinery is designed with a focus on quality and performance, incorporating components from globally recognized brands. One of the standout features of our equipment is the use of Siemens PLCs and Festo pneumatic systems. Siemens PLCs offer unmatched precision, reliability, and ease of operation, ensuring seamless control of the production process.

Festo pneumatic systems complement this by delivering robust, energy-efficient, and durable solutions for automation. Together, these premium components enhance the performance, efficiency, and longevity of our machines. By relying on trusted brands, we ensure our customers benefit from cutting-edge technology, reduced downtime, and optimized productivity.

MARAMICO

Premium Components for Superior Performance

Using the Best Brands in PLC and Pneumatic Systems

Our machinery is designed with a focus on quality and performance, incorporating components from globally recognized brands. One of the standout features of our equipment is the use of Siemens PLCs and Festo pneumatic systems. Siemens PLCs offer unmatched precision, reliability, and ease of operation, ensuring seamless control of the production process.

Festo pneumatic systems complement this by delivering robust, energy-efficient, and durable solutions for automation. Together, these premium components enhance the performance, efficiency, and longevity of our machines. By relying on trusted brands, we ensure our customers benefit from cutting-edge technology, reduced downtime, and optimized productivity.

M

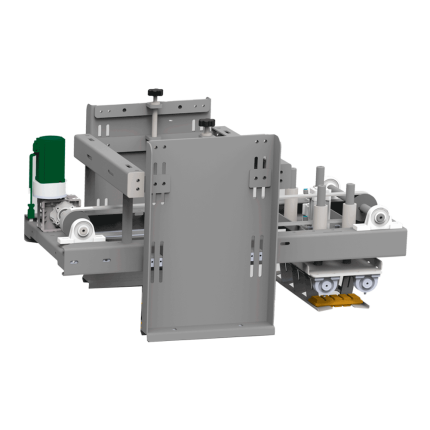

Custom Machinery for Ice Cream and Hot Liquid Filling

At Marami Machinery, we specialize in manufacturing a wide range of filling machines tailored to our customers’ needs. In addition to our renowned ice cream fillers, we also produce machines for filling hot liquids such as date syrup.

Our team works closely with customers to design and build equipment that meets their specific production requirements. Whether you need a specialized filling line for hot liquids or a custom solution for another product, we are here to deliver advanced, reliable, and efficient machinery.

Advanced Control and Monitoring

Advanced Control and Monitoring

Advanced Control and Monitoring with Siemens PLC Technology

Advanced Control and Monitoring with Siemens PLC Technology

Our machines are equipped with a central PLC, allowing for precise control of product output and easy parameter adjustments. The entire process, from startup to the final product, is seamlessly managed by the central PLC. One of the standout features of our machines is the use of Siemens controllers, which enhance reliability, performance, and ease of operation. The processing data is displayed on a large touchscreen panel with a simple and user-friendly interface.

Remote Access Managment

In addition, a remote PLC access and control service is available as an optional feature for customers, enabling better management and monitoring capabilities.

Double the Variety, One Efficient Line!

Double the Variety, One Efficient Line!

Dual-Purpose Ice Cream Filling Lines

Our linear ice cream filling machines offer a unique feature tailored to meet diverse production needs. Customers can simultaneously produce two different types of ice cream with distinct packaging formats on the same production line.

This capability allows for greater flexibility, enabling businesses to expand their product range without investing in multiple machines. At Marami Machinery, we call this innovative solution the dual-purpose production line, designed to enhance efficiency and meet market demands effectively.

At Marami Machinery, we understand that every production process is unique. That’s why we offer fully customizable solutions to meet your specific requirements. Whether you need specialized filling machines for ice cream, hot liquids, or other products, we design and build equipment to match your production goals.

Persian – فارسی

Persian – فارسی Kurdish

Kurdish Arabic

Arabic Turkish

Turkish Russian

Russian Dutch

Dutch italian

italian

Persian – فارسی

Persian – فارسی

Reviews

There are no reviews yet.