M

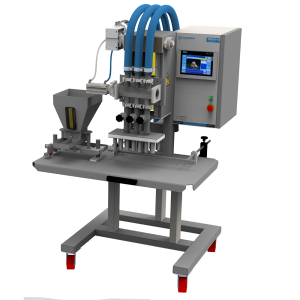

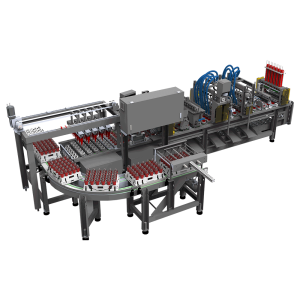

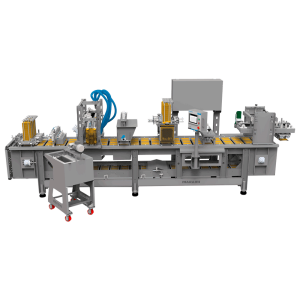

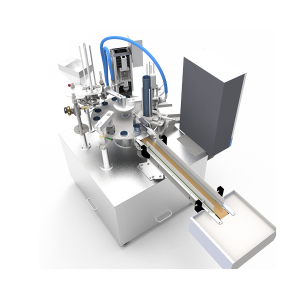

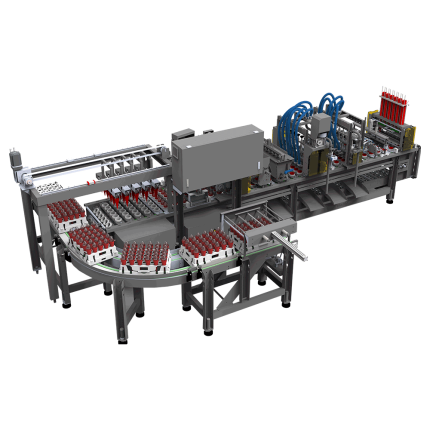

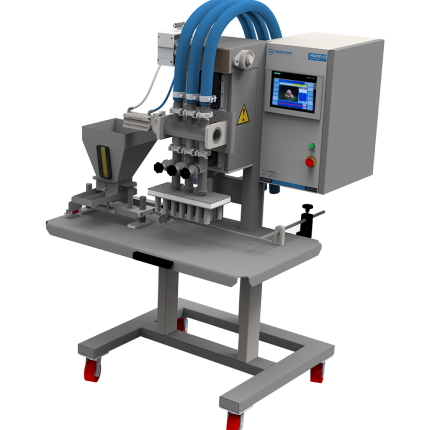

Twin-Tank Sauce Mixer: Optimized for Continuous Production

The Twin-Tank Sauce Mixer is designed to streamline production by allowing manufacturers to add semi-thick liquids, such as caramel ripple sauce or chocolate syrup, to their products without halting the production line. This innovative system enhances efficiency and ensures smooth operations in any production setup.

Large Twin-Tank Mixer

- Capacity: Each tank holds up to 30 liters, enabling a higher volume of sauce mixing.

- Key Features:

- Continuous operation: The dual-tank system allows one tank to be recharged while the other is in use, ensuring the production line never stops.

- Ideal for large-scale operations requiring consistent addition of semi-thick liquids like caramel or chocolate sauces.

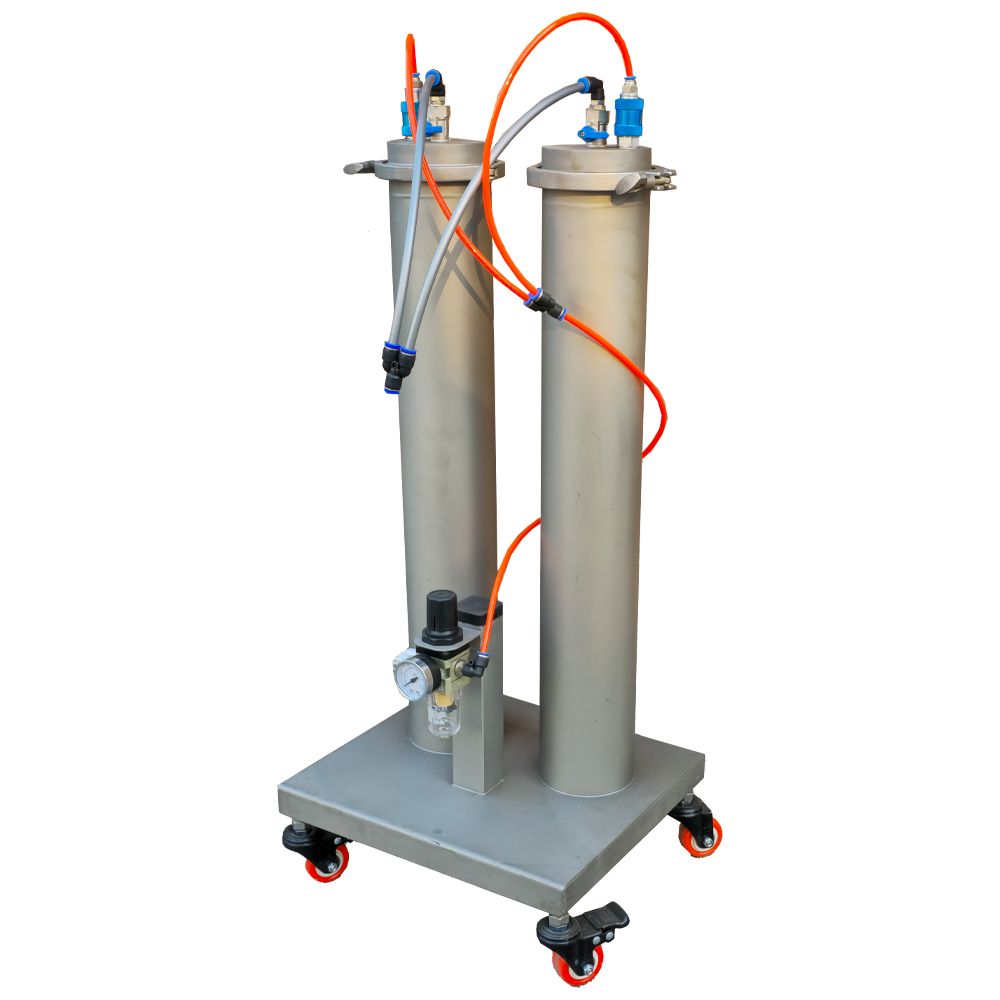

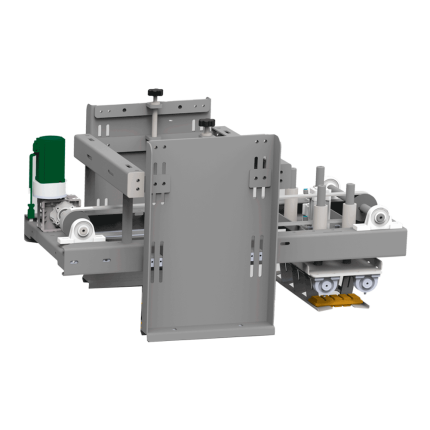

Small Twin-Tank Mixer

- Capacity: Each tank holds 8 liters, designed for smaller production setups.

- Key Features:

- Similar to the larger model, this version offers the convenience of continuous production by enabling individual tank refilling without halting the line.

- Perfect for smaller machinery and operations requiring compact solutions.

MARAMICO

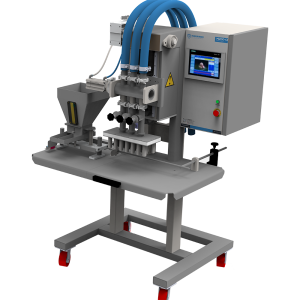

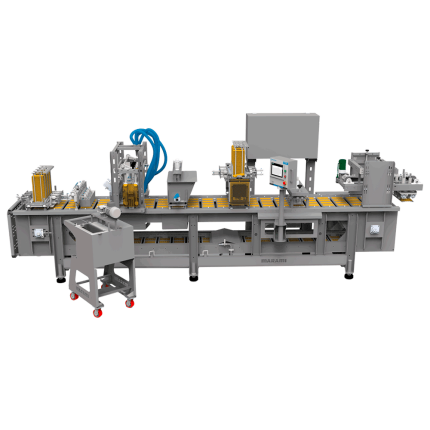

Premium Components for Superior Performance

Using the Best Brands in PLC and Pneumatic Systems

Our machinery is designed with a focus on quality and performance, incorporating components from globally recognized brands. One of the standout features of our equipment is the use of Siemens PLCs and Festo pneumatic systems. Siemens PLCs offer unmatched precision, reliability, and ease of operation, ensuring seamless control of the production process.

Festo pneumatic systems complement this by delivering robust, energy-efficient, and durable solutions for automation. Together, these premium components enhance the performance, efficiency, and longevity of our machines. By relying on trusted brands, we ensure our customers benefit from cutting-edge technology, reduced downtime, and optimized productivity.

MARAMICO

Premium Components for Superior Performance

Using the Best Brands in PLC and Pneumatic Systems

Our machinery is designed with a focus on quality and performance, incorporating components from globally recognized brands. One of the standout features of our equipment is the use of Siemens PLCs and Festo pneumatic systems. Siemens PLCs offer unmatched precision, reliability, and ease of operation, ensuring seamless control of the production process.

Festo pneumatic systems complement this by delivering robust, energy-efficient, and durable solutions for automation. Together, these premium components enhance the performance, efficiency, and longevity of our machines. By relying on trusted brands, we ensure our customers benefit from cutting-edge technology, reduced downtime, and optimized productivity.

M

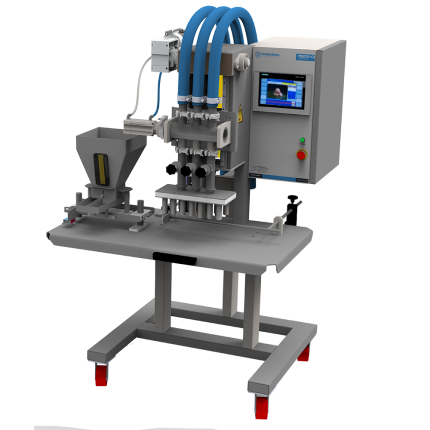

Why Choose the Marami Twin-Tank Sauce Mixer?

- Uninterrupted Production: The dual-tank system ensures no downtime as one tank can be refilled while the other continues to operate.

- Flexibility in Use: Both tanks are independent, making it easy to manage different sauces or refill needs during production.

- Scalable Options: The availability of large and small tank sizes makes the mixer suitable for diverse production lines.

Persian – فارسی

Persian – فارسی Kurdish

Kurdish Arabic

Arabic Turkish

Turkish Russian

Russian Dutch

Dutch italian

italian

Persian – فارسی

Persian – فارسی

Reviews

There are no reviews yet.